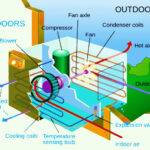

Thermal transfer in an air conditioner happens in the evaporator and condenser coils, also called fins. The evaporator coils suck in heat from the indoor air and cool the air. The condenser coils give off heat and warm the outside air. For efficient heat transfer between the coils and the atmosphere, the former must be free of water, dirt and deposits. But that is rarely possible as the air, no matter where you are, contains salts and acids that have a corrosive effect on the coils.

Table of Contents

Corrosion In Air Conditioners

Corrosion of the fins can be greatly damaging for an air conditioner. It hampers cooling and causes leaks that can be difficult to fix. Humid places where the air is heavy with water vapor and places close to the sea or ocean where the air is salty and moist, experience a higher level of corrosion than dry places. Let us try and understand how corrosion happens and what can be done to avert it.

Air conditioner fins are made of aluminum or copper. Aluminum is a cheaper option, but copper is more preferable as it has higher heat conductivity which mean it is better at heat exchange. It is also more malleable and has a higher tolerance for stress. It has a greater tensile strength and does not break easily upon impact.

Galvanic Corrosion

Due to the high cost of copper, air conditioner manufacturers often use a combination of the two metals by welding the aluminum part to the copper tubes. This is a cost-effective solution, but far from ideal as it gives rise to a condition known as galvanic corrosion, also called bimetallic corrosion.

Galvanic corrosion happens when two different metals are in contact with each other in the presence of an electrolyte which in this case is water. It is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another metal in an environment that contains an electrolyte.

However, if only one metal is used to make the fins, the issue of galvanic corrosion can be prevented. But, to stay more pocket-friendly and within the reach of the average Indian consumer, companies still use this technique to make condensers and evaporators. The result is corroded coils, slower heat exchange and inefficient cooling.

Formicary Corrosion

Pure copper suffers from formicary corrosion. Formicary corrosion mainly occurs in copper and copper-based alloys. It is commonly observed in the heat exchangers of HVAC (heating, ventilation and air conditioning) systems as they are principally made of copper.

Formicary corrosion is a chemical reaction between oxygen, water and an organic acid. If one of them is missing or removed, corrosion cannot take place. Studies have shown that in 90% of the cases, the organic acids come from household products like cleaning solvents, deodorants, cosmetics, paints and plywood furniture. These acids fall under a larger group of harmful indoor air pollutants known as VOCs or volatile organic compounds.

Acids like formic acid and acetic acid are frequently found in the indoor air of homes. Among other perils, they penetrate air conditioning systems and induce formicary corrosion in the copper fins of the machine.

But, formicary corrosion is a fairly manageable hazard. With regular cleaning and maintenance, it can be kept under control, although it is not an ideal situation. It increases the maintenance and running cost of the air conditioner, which is not desirable. Plus, corrosion of any kind is bad for an air conditioner and needs to be stopped at all cost.

Some experts seem to suggest that installing a heat recovery ventilation system or an energy recovery system could stop formicary corrosion. Their view is that the increased number of air changes would thwart corrosion as there would be less organic acids in the air. However, more research is needed in this area and nothing conclusive can yet be said about the effectiveness of such systems.

How To Prevent Corrosion In Air Conditioners

In this article, we are going to talk about 3 main technologies for the prevention of corrosion in HVAC systems. These are:

- Blue Fin Technology

- Gold Fin Technology

- Micro-Channel Condenser Coil Technology

Let’s begin.

Blue Fin Technology

Blue Fin technology is the practice of coating the evaporator and condenser fins with epoxy, a kind of resin. Epoxy is a common name given to cured or uncured prepolymers and polymers that contain the epoxide functional group. Epoxy resins are cured to form thermoset polymers that have a high degree of resistance to chemicals and solvents, and adhere firmly to a wide range of substrates. They display high tensile, fatigue, compressive and flexural strength which makes them flexible and resistant to impact and abuse. They have low shrinkage on cure and are unaffected by corrosion. They exhibit outstanding electrical insulation and temperature tolerance.

Due to the excellent weather-resistivity of epoxy resins, they are frequently used in HVAC systems to prevent corrosion. Epoxy is a hydrophilic compound that does not allow water to settle on it for too long. It has low surface tension, meaning it has low friction which makes water droplets slide off easily.

The friction coefficient between the water and the coated surface is very low which prevents water from collecting on the fins. The excess water is drained out through an outlet and the enclosure stays clean. This prevents harmful microbes like bacteria, fungi and viruses from breeding in the gadget and causing diseases.

Epoxy does not react with atmospheric salts and acids. It prevents them from being deposited on the fins. It ensures the fins don’t get clogged so that air can move more freely between them. This prolongs the life of the air conditioner as it does not have to work extra hard to push air through fins clogged with deposits. It reduces the stress on the machine and prevents break-downs.

Another benefit of epoxy is that it protects the fins from humidity in hot and salty environments. Experiments have shown that aluminum coils with a blue coating of epoxy last thrice as long as uncoated aluminum coils when subjected to a 5% sodium chloride (common salt) mist.

As per the results, epoxy-coated coils lasted 500 hours whereas naked coils lasted only 150 hours. Further, when the temperature of the coils was increased to 200 ᵒC for 5 minutes, the coating did not exhibit any change in texture, composition or efficiency. This proves that epoxy is a hardy resin with excellent weatherproofing properties. No wonder it is so extensively used in air conditioning.

Gold Fin Technology

Gold Fin technology is a method of coating air conditioner coils with a water-resistant anti-corrosive gold nano coating. The coating forms a physical barrier between the coil and the environment and protects it from environmental decay. It is impervious to water, salts, acids and dirt. It doesn’t allow water droplets to settle on the coils and checks of deposition of salts and acids. It prevents rusting and corrosion, and improves the overall efficiency of the machine. Gold Fin technology keeps the air conditioner in good working condition. It hastens cooling and conserves electricity. Companies like IFB use titanium dioxide as the gold coating material.

The main difference between Golf Fin and Blue Fin technology is in the composition of their coatings. Gold Fin uses a gold nano coating like titanium dioxide whereas Blue Fin uses epoxy resins. Both are done to protect the fins from corrosion.

Micro-Channel Condenser Coil Technology

Micro-Channel Condenser Coil technology is used by Samsung. Under this technology, the condenser has a slightly different construction. Its fins are made up of multiple flat aluminum tubes with numerous micro-channels for the refrigerant to pass through.

The new design reduces air resistance, and speeds up heat exchange and cooling. It does away with the problem of galvanic corrosion as it needs just one metal, aluminum. It also makes the condenser more compact which means you have a smaller outdoor unit that’s more portable and easier to install in narrow spaces.

Samsung has branded this technique Multi Jet Technology. It features in several of its high-end air conditioners. Samsung combines it with Durafin technology which protects the condenser from atmospheric moisture, salts and acids. Under Durafin, the fins are coated with a mixture of chromium and zirconium to make resistant to corrosion, especially in coastal regions where the air is salty and humid.

Pro Tips : Air conditioning systems are better option for humid summers in India.